Beginning June 1, Ingram will make its Jackson, Tenn., warehouse the single shipping point for its distributed lines, including Consortium Book Sales & Distribution, Ingram Academic, Ingram Publisher Services, Publishers Group West and Two Rivers.

Beginning June 1, Ingram will make its Jackson, Tenn., warehouse the single shipping point for its distributed lines, including Consortium Book Sales & Distribution, Ingram Academic, Ingram Publisher Services, Publishers Group West and Two Rivers.

The move, the company says, will result in simplified ordering and shipping, improved stock availability information, a single returns location and other benefits for distributed titles.

With the change, booksellers must order Ingram Distribution titles from the Jackson warehouse to receive the Publisher Direct discount; orders of distributed titles from the other Ingram warehouses in Ft. Wayne, Ind., La Vergne, Tenn., Chambersburg, Pa., and Roseburg, Ore.--all Ingram Wholesaling facilities--will be sold at the less-advantageous wholesale discount.

Ingram is also changing its free shipping policies. For five years, indies have been able to receive free freight on 15 or more titles combining both distribution and wholesale orders. As of June 1, orders can't be combined for free freight, but the minimum for free freight for distributed titles, from the Jackson warehouse, will be reduced to 10 copies. (The minimum for free freight remains 15 for wholesale orders.)

The changes have caused concern among some West Coast indie booksellers who fear that they won't receive distributed titles in a timely way, going from a day or two for shipping to up to a week, and that they'll cost more.

However, Mark Ouimet, v-p and general manager of IPS, PGW and Consortium, said that in anticipation of the change, Ingram, which previously shipped from Jackson twice a week, on Tuesdays and Fridays, is now moving to shipping and processing every day, Monday through Friday. Orders received by 1 p.m. Eastern will begin processing the same day. Current estimated shipping times from Jackson range from one day in nearby states to two days in the South, much of the Midwest and as far northeast as New York; three days in most of New England, most of the Rocky Mountain states and most of California; and four days for Oregon, Washington and parts of California, Nevada, Idaho, Arizona and Colorado.

Ouimet said that although he can't talk about the efforts in detail yet, Ingram is "looking at ways to get books quicker to the West Coast" and has begun instituting several changes to do that.

As of June 1, on-hand stock levels at Jackson will be visible on Ingram's IPS cart on ipage. Jackson is established as a DC for IPS only, and is not a Ingram Wholesale warehouse. On ipage, a bookseller can place an order for Jackson using the "IPS-Publisher Direct Discount Cart." Orders can be placed on POS systems with the IPS SAN 6318630. Ingram noted that it is working with IndieCommerce to have Jackson inventory display on it by June 1.

Ouimet emphasized that Ingram already ships all new title releases from Jackson all over the country, even while many West Coast indies have ordered backlist from the Roseburg, Ore., warehouse.

He called the June 1 shift the last part of an 18-month effort to centralize distributed titles in Jackson. (Some IPS Distribution publishers were previously centralized in Ingram's Chambersburg, Pa., warehouse.) Having bookstores' IPS Distribution titles all shipped from Jackson is, he said, "the last piece of the puzzle for centralizing. Instead of moving books all over the country, we can focus on having everything come from Jackson."

Ouimet said, too, that the company is hosting weekly q&a sessions on Zoom about the Jackson warehouse, on Wednesdays through June 30, at 10 a.m. Pacific/1 p.m. Eastern. Booksellers are encouraged to "bring your questions." Ingram also has information online about IPS Distribution changes, with a FAQ section.

Ingram acquired the Jackson warehouse in 2016 when it purchased Perseus's distribution operations, which included Consortium, PGW, and Perseus Distribution. Since then, Ingram has, it says, made the warehouse "a highly efficient, state-of-the-art facility" by investing heavily in several areas; these include, among other things, moving the warehouse management system to Ingram's, PKMS, and shifting to Ingram's order-management system; reconfiguring the pick system at the American Drive facility; switching from air pillow to paper fill; and improving carton quality.

Rofhiwa Book Café hosted its grand opening celebration Saturday at 406 South Driver St. in Durham, N.C., posting on Facebook: "We're still reeling from this past weekend. All that love. The flowers. The well-wishes. So much joy and laughter and life! Thank you for holding us up."

Rofhiwa Book Café hosted its grand opening celebration Saturday at 406 South Driver St. in Durham, N.C., posting on Facebook: "We're still reeling from this past weekend. All that love. The flowers. The well-wishes. So much joy and laughter and life! Thank you for holding us up."

SHELFAWARENESS.0213.S4.DIFFICULTTOPICSWEBINAR.gif)

SHELFAWARENESS.0213.T3.DIFFICULTTOPICSWEBINAR.gif)

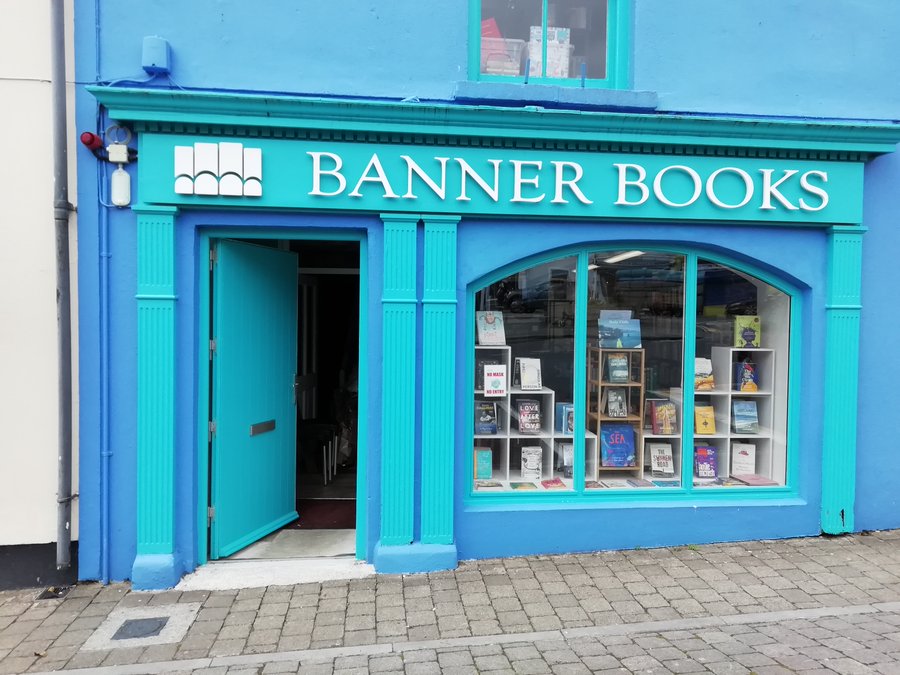

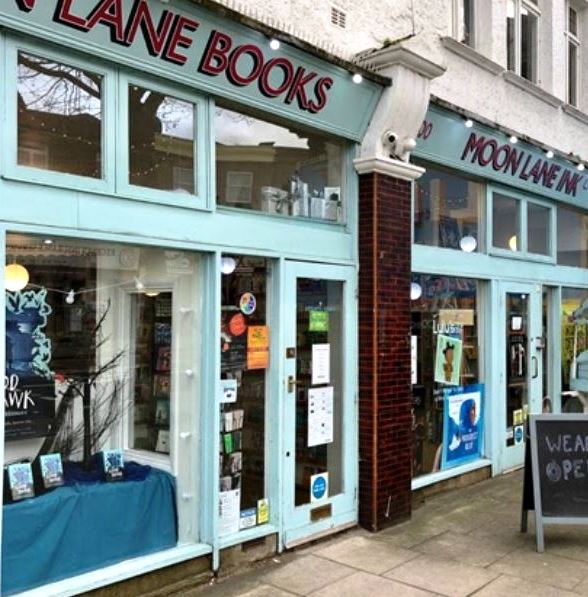

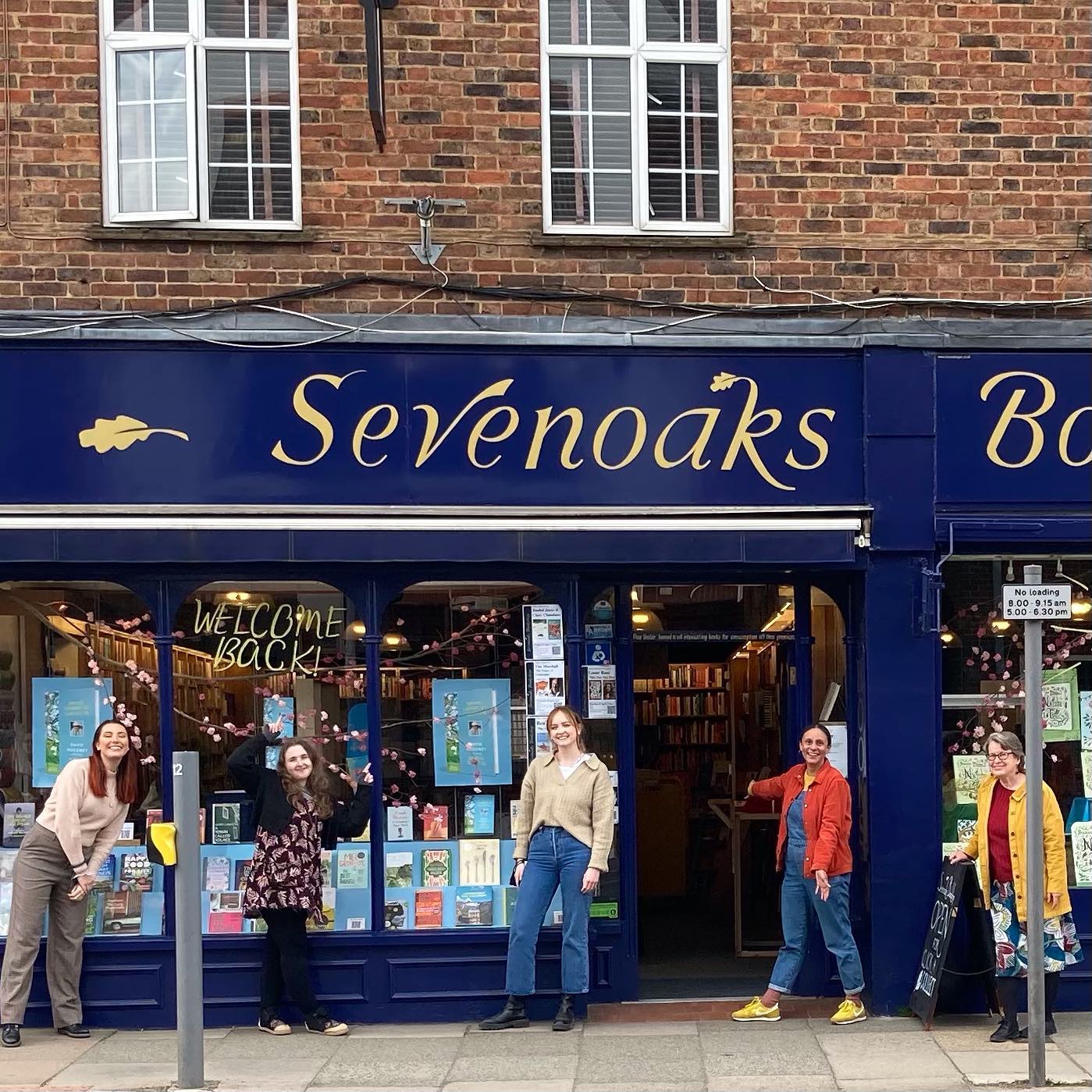

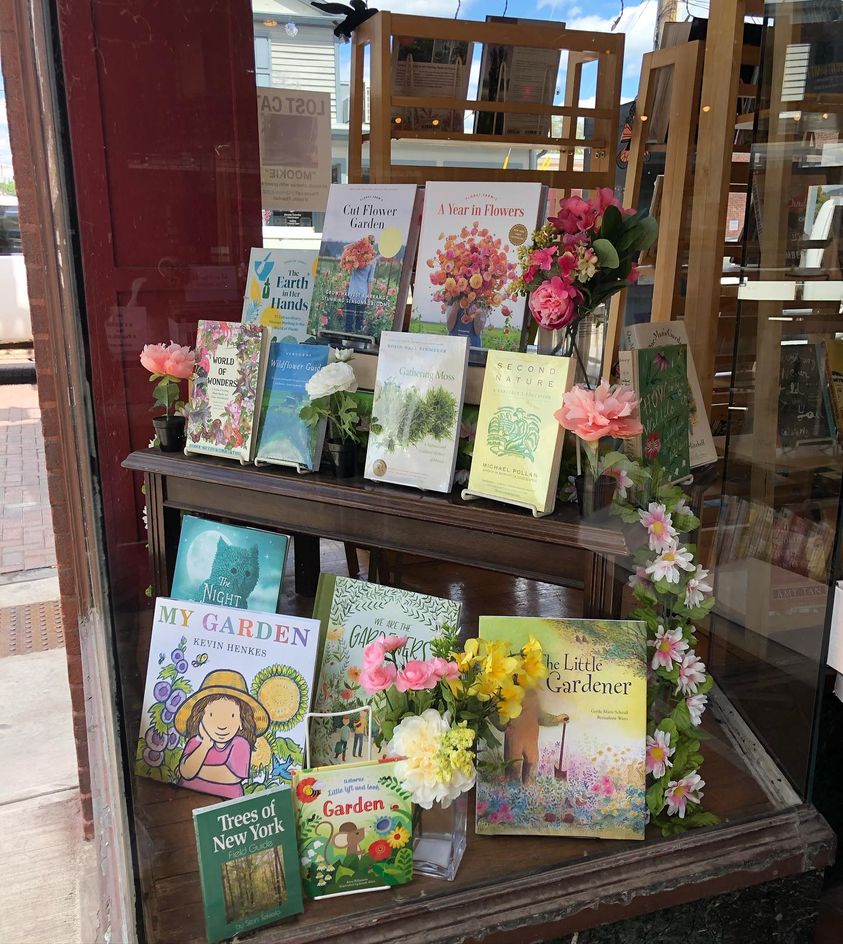

Indie booksellers were in a celebratory mood on Twitter. Among those sharing the joy of reopening were

Indie booksellers were in a celebratory mood on Twitter. Among those sharing the joy of reopening were  Some booksellers had taken advantage of the lockdown for a little facelift, including

Some booksellers had taken advantage of the lockdown for a little facelift, including  Congratulations to the

Congratulations to the  "I'm full of praise and wonder for

"I'm full of praise and wonder for  Beginning June 1, Ingram will make its Jackson, Tenn., warehouse the single shipping point for its distributed lines, including Consortium Book Sales & Distribution, Ingram Academic, Ingram Publisher Services, Publishers Group West and Two Rivers.

Beginning June 1, Ingram will make its Jackson, Tenn., warehouse the single shipping point for its distributed lines, including Consortium Book Sales & Distribution, Ingram Academic, Ingram Publisher Services, Publishers Group West and Two Rivers.

Spirit Tech: The Brave New World of Consciousness Hacking and Enlightenment Engineering

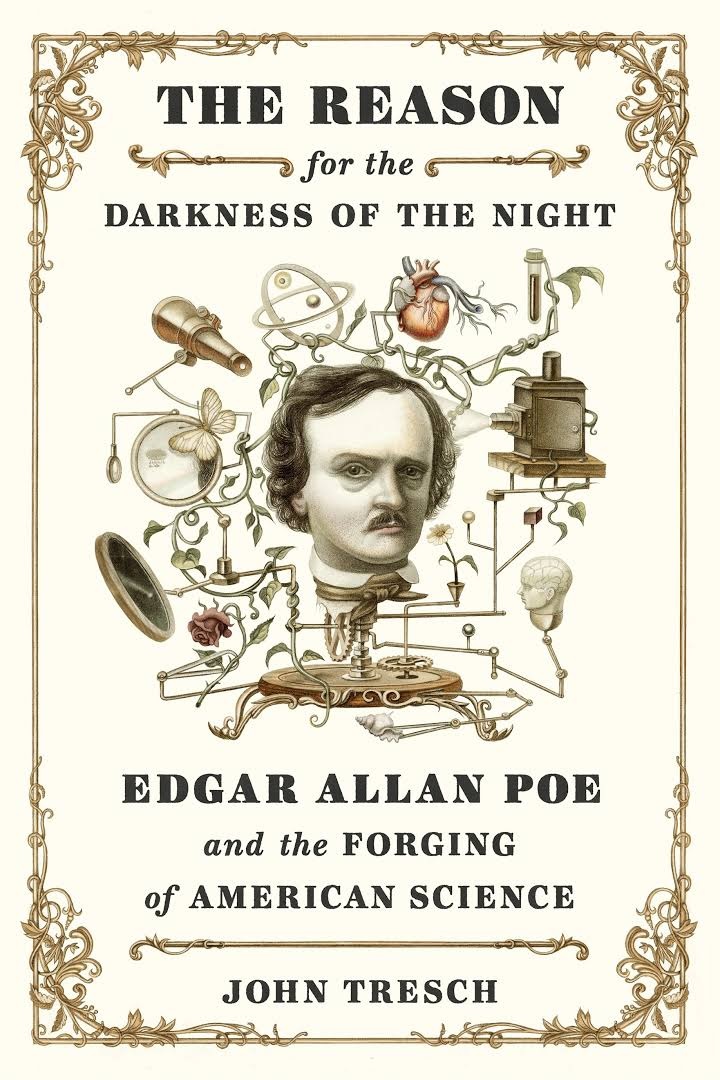

Spirit Tech: The Brave New World of Consciousness Hacking and Enlightenment Engineering Mention Edgar Allan Poe to most readers and the name will conjure a chilling memory of a macabre tale like "The Pit and the Pendulum," or perhaps an image of a tortured artist who died young. It's almost certain those associations won't connect the writer to the world of science.

Mention Edgar Allan Poe to most readers and the name will conjure a chilling memory of a macabre tale like "The Pit and the Pendulum," or perhaps an image of a tortured artist who died young. It's almost certain those associations won't connect the writer to the world of science.